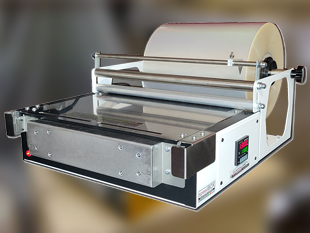

With over 46 years of experience in the Packaging Industry, we have a lot of knowledge in the art of wrapping packages in many different ways. In recent years, we have specialised in the art of overwrapping, which is often referred to as cellowrapping.

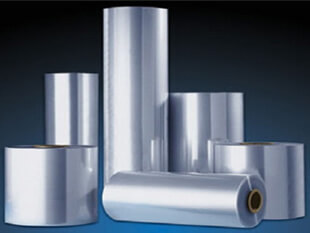

The cellowrap term came from the early use of Cellophane as the primary wrapping product, which is a paper based film. In today’s world, most client use Biaxially Oriented Polypropylene (BOPP), as it is easier to use with most applications and, as with Cellophane, it is recyclable.

Contact us for more information on our range of machines and film supply service.